However, sourcing them can be difficult and risky and comes with many challenges, such as quality concerns, counterfeits, and unreliable suppliers. In this article, UniBetter will explain what obsolete components are and why they matter while offering six important tips to help businesses source them more effectively and securely.

Picture from:

https://unsplash.com/photos/three-black-ics-attached-on-green-pcb-board-5lIGl0a0Qzw?utm_content=creditShareLink&utm_medium=referral&utm_source=unsplash

What Are Obsolete Electronic Components?

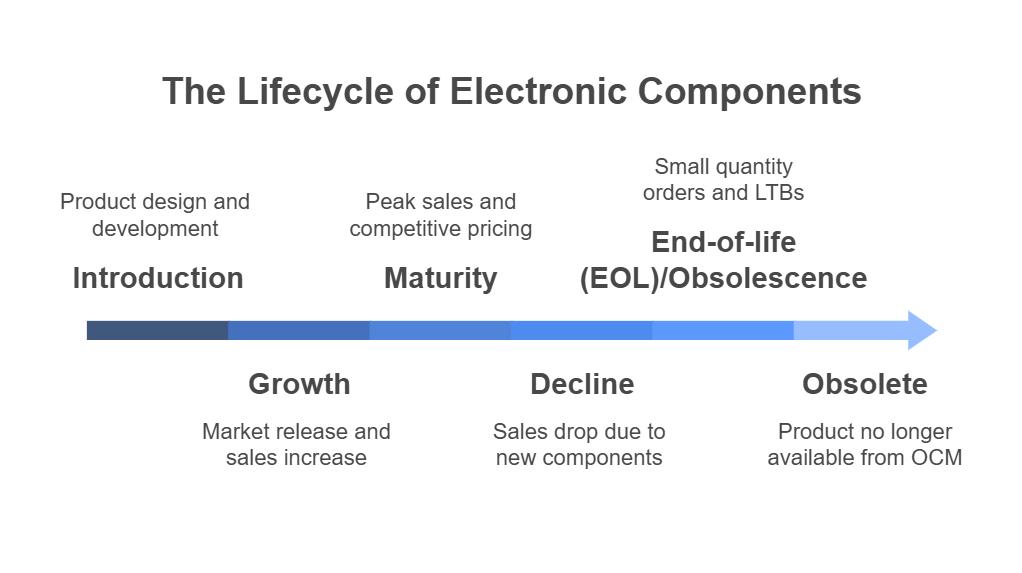

1. Understanding Obsolescence in Electronics

In the electronics supply chain, a component becomes obsolete when the original manufacturer permanently stops its production and removes it from active inventory. This is usually marked by an official end-of-life notification and means the component will no longer be available through authorized channels.

2. Common Causes of Electronic Component Obsolescence

- Manufacturer End-of-Life (EOL) Announcements

Manufacturers may issue EOL announcements due to decreased demand or increased production costs.

- Component Redesigns or Updates

Product redesigns or updates can render older versions obsolete.

- Material Shortages

Shortages of specific raw materials may lead to the discontinuation of parts.

- Shifts in Industry Standards (e.g., RoHS Compliance)

Changes in industry standards, like RoHS compliance, can result in the withdrawal of parts that do not meet new regulatory requirements.

3. Importance of Obsolete Parts in Electronics

Although they are no longer manufactured, many industries still rely on these components to operate efficiently. They are mainly used in legacy systems that continue to operate reliably and in long-lifecycle products where full redesign is not feasible. Continued access to these parts is necessary to ensure consistent system performance, prevent operational disruptions, and avoid the high costs associated with replacing entire units.

Risks of Using or Sourcing Obsolete Components

Using obsolete electronic parts involves several risks that can directly impact system reliability, compliance, and overall project timelines.

1. Quality Degradation and Storage Issues

One of the primary concerns is quality degradation, especially when components have been stored for long periods without proper environmental controls. Exposure to moisture, dust, or electrostatic discharge can reduce the functionality of these parts and lead to unexpected failures during operation.

2. Risk of Counterfeits in Gray Markets

When obsolete components are no longer available through authorized channels, buyers may turn to gray markets. These independent sources often lack rigorous verification, increasing the risk of counterfeit, relabeled, or non-functional parts.

3. Limited Warranty or No Support from OEMs

Once production ends, original equipment manufacturers typically cease offering warranties, updates, and technical support. This lack of support creates challenges for system integration, maintenance, and long-term reliability.

4. Potential Compliance Issues

Older components may not meet current environmental or safety regulations, posing compliance risks, especially in industries with strict regulatory standards such as the medical, automotive, or aerospace sectors.

5. Long Lead Times and Rising Costs

Finally, as obsolete electronic components become harder to find, lead times increase and prices often surge. This scarcity can lead to procurement delays and make budgeting and planning more difficult for engineering and production teams.

However, it is still possible to successfully source obsolete electronic components through the proper methods.

6 Tips for Sourcing Obsolete Electronic Components Easily

Here are some essential tips to acquire obsolete electronic components:

Tip 1: Start with the Original Manufacturer or Authorized Distributors

Begin by reaching out to the original manufacturer or their authorized distribution partners. They may still have limited stock or offer last-time buy options, which are the most reliable sources in terms of authenticity and documentation.

Tip 2: Use Trusted Electronic Component Search Engines

Use specialized search engines, such as Octopart and Sourcengine, that collect inventory listings from verified suppliers. These platforms help you quickly check availability, compare options, and filter results based on technical requirements and certifications.

Tip 3: Work with Verified Independent Distributors or Brokers

If the part is no longer available through official channels, turn to independent distributors with recognized industry certifications. Before placing any orders, review their quality control procedures and ask for client references to confirm their credibility.

Learn more about independent distributors and distribution channels:

Why Work with Independent Distributors for Component Needs?

Different Types of Distribution Channels for Electronic Components

Tip 4: Consider Alternative or Cross-Reference Parts

When the original component is unavailable, search for equivalents using manufacturer cross-reference tools. Review datasheets carefully and test alternatives before approval to ensure compatibility with your system’s design.

Tip 5: Request Part Testing and Quality Certifications

When buying from non-authorized sources, always request component testing and quality documentation. Ask for certificates of conformance, full test reports, and traceability records to verify the part’s condition and origin.

Tip 6: Build an Obsolescence Management Strategy

Try to establish a system to track the lifecycle status of critical components. Monitor end-of-life announcements, identify substitutes in advance, and plan inventory early to avoid unexpected shortages or production delays.

UniBetter Recommendation

UniBetter is a proven obsolete electronic components distributor for sourcing obsolete and hard-to-find electronic components. With over 15 years of experience and a global network of 7,000 verified suppliers, we serve more than 3,000 clients across key industries, including medical, automotive, energy, and industrial control.

Our CSD Quality Management System ensures every component is thoroughly inspected and traceable. We also offer fast BOM quotes, alternative part support, and excess stock management, helping businesses maintain supply continuity and reduce downtime.

In short, you can rely on UniBetter for:

- 100% authentic components

- Rigorous multi-level quality inspections under the CSD system

- Compliance with ISO 9001:2015, ISO 13485:2016, AS9120:2016, ANSI/ESD S20.20, CNAS standards, and more.

- Fast BOM quotations within 2 hours by 30+ global sourcing experts

- Access to over 7,000 reliable suppliers for rare and obsolete components

- Industry-specific solutions across automotive, medical, industrial, IoT, communications, energy sectors, and beyond.

Wrapping Up

Obsolete electronic components can be challenging to source, but with the right strategy and a trusted supplier like UniBetter, you can secure reliable parts and maintain uninterrupted operations.

If you are facing supply chain disruptions or struggling to locate discontinued parts, UniBetter is here to help. Our expert team offers fast responses, alternative solutions, and full quality assurance to meet your exact needs.

Get in touch with us today to discuss your component requirements and experience a dependable sourcing partner committed to your success.