Electronic component sourcing can face different challenges due to global supply constraints, unpredictable pricing, and extended lead times. These issues can pose significant pressure on procurement teams across all industries.To maintain cost control and avoid production delays, companies must adopt more efficient and strategic sourcing methods. In this article, UniBetter will present you with seven practical and proven tips to reduce electronic component sourcing costs.

Picture from

https://unsplash.com/photos/flat-lay-photography-of-circuit-board-zP7X_B86xOg?utm_content=creditShareLink&utm_medium=referral&utm_source=unsplash

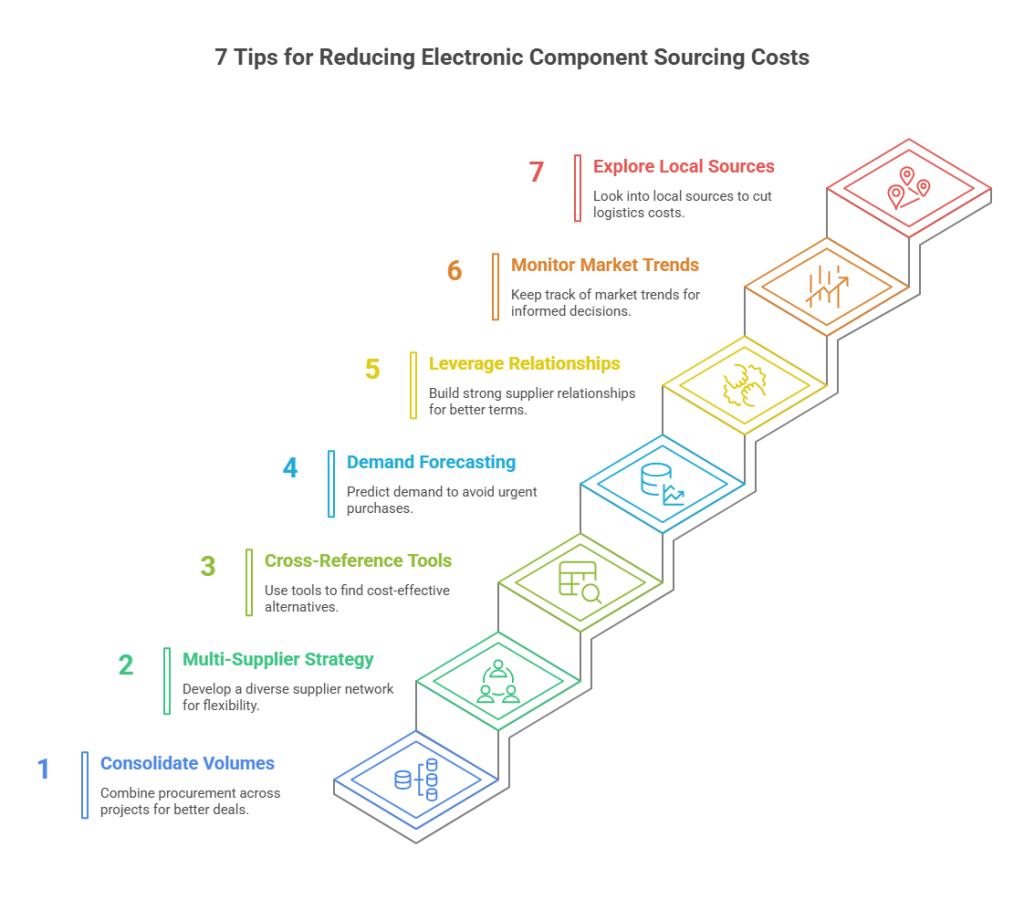

7 Actionable Tips to Reduce Component Procurement Costs

Here are 7 crucial tips for sourcing high-quality electronic components at competitive prices.

Tip 1: Consolidate Your Procurement Volumes Across Projects

When individual teams or departments manage electronic component procurement separately, the process becomes fragmented, and cost-saving opportunities are often overlooked.

Consolidating purchase volumes across all internal projects enables your organization to place one larger and more coordinated order with suppliers. Large sourcing orders improve your ability to negotiate for better pricing, stronger delivery terms, and more responsive service.

It also simplifies part standardization, improves inventory tracking, and reduces unnecessary administrative repetition. Suppliers are more inclined to prioritize bulk buyers when inventory tightens, giving your business a practical advantage during periods of supply instability.

Tip 2: Build a Multi-Supplier Strategy for Flexibility and Leverage

Relying solely on a single supplier exposes your operation to considerable risk, particularly when delays, shortages, or price changes occur. A strategy that includes multiple qualified suppliers provides flexibility in how and where you source key components. It enables you to shift orders based on availability, lead time, and the cost of electronic components.

More information about distributors and distribution channels:

Why Work with Independent Distributors for Component Needs?

Different Types of Distribution Channels for Electronic Components

Tip 3: Use Cross-Referencing Tools to Identify Cost-Effective Alternatives

Electronic component sourcing is more efficient when you are not restricted to a single brand or part number. Cross-referencing tools allow you to find compatible parts from other manufacturers that meet the same technical specifications. These tools help procurement teams explore alternative options that are often more affordable or available with shorter lead times.

This is particularly valuable when an original part becomes obsolete, enters allocation, or experiences a sudden cost increase. Once approved by engineering teams, such substitutes can help maintain production flow while reducing overall procurement costs.

Tip 4: Invest in Demand Forecasting to Avoid Urgent Purchases

Unexpected orders tend to drive up procurement costs due to limited availability, rush shipping, and higher pricing. Investing in demand forecasting allows companies to anticipate future needs and plan purchases in advance.

By analyzing historical usage, production timelines, and upcoming project demands, businesses can easily secure required inventory at more favorable rates. Forecasting also strengthens supplier coordination and improves scheduling. When planned correctly, it reduces last-minute purchases that may strain budgets and lead to supply gaps.

Tip 5: Leverage Long-Term Supplier Relationships for Better Terms

Suppliers typically offer more favorable terms to buyers who provide consistent and reliable business. Building long-term partnerships with trusted electronic component sourcing vendors allows for better pricing, early access to inventory during shortages, and more flexible credit arrangements.

These advantages are not usually extended to one-time or irregular buyers. Established relationships also provide earlier insight into upcoming changes in availability, pricing, or product status. This allows your team to adjust procurement plans ahead of time.

Tip 6: Monitor Market Trends and Benchmark Pricing Regularly

Component prices are influenced by a range of external factors, including raw material costs, global demand, production capacity, and currency movement. If you do not monitor these trends, you may unknowingly continue purchasing at above-market rates.

Regular benchmarking allows you to compare current supplier prices with real-time market data. This insight strengthens your position during negotiations and highlights opportunities to renegotiate contracts.

Tip 7: Explore Local or Regional Sources to Reduce Logistics Costs

Sourcing components from international suppliers may result in high shipping costs and long lead times. While overseas pricing may seem attractive, the total landed cost may exceed expectations once all fees are included.

Local and regional suppliers can reduce these risks by offering faster delivery, more transparent logistics, and easier communication. This can be especially useful for time-sensitive orders or when inventory storage is limited. In many cases, local electronic component sourcing improves supply chain responsiveness and lowers overall procurement costs.

UniBetter Recommendation

UniBetter is a global distributor with over 15 years of experience in electronic component sourcing. Trusted by more than 3,000 clients worldwide, we operate seven global offices to reduce sourcing costs through fast service, expert support, and broad supplier access.

With a network of over 7,000 reliable suppliers, we quickly source both standard and hard-to-find components. This helps businesses avoid costly production delays and inflated prices during shortages. Our team of over 30 global sourcing specialists identifies cost-effective alternatives and delivers competitive quotes, often within two hours.

We support our customers through Six Major Services: Shortage Supply, Turnkey Procurement, Cost Savings, Obsolescence, Franchised Products & Design Support, and Excess Management. This comprehensive service model helps minimize purchasing errors and shorten lead times, reducing overall procurement expenses. For discontinued or obsolete parts, we secure replacements early to avoid costly redesigns or delays.

Wrapping Up

Reducing electronic component sourcing costs requires smart planning, reliable suppliers, and a smart strategy. UniBetter is a trusted partner in this regard. With global reach, fast service, and proven sourcing solutions, we help you lower costs and secure quality components.

Don’t let sourcing challenges slow down your operations. Contact UniBetter today to discover how our cost-effective services can streamline your supply chain and keep your business moving forward.